Tehnomont , poduzeće za montažu, proizvodnju, brodogradnju i nautički turizam; nastalo je 1956. u Puli kao mala radionica za izvođenje montažnih radova. Sljedećih desetak godina intenzivno se probijao na međunarodnom tržištu, izvodeći složene montažerske radove na postrojenjima u Iraku, Egiptu, Alžiru, Italiji, Austriji…

Danas Tehnomont čine dva društva :

Brodogradilište Pula d.o.o ( koje u sastavu ima Brodogradilište, Investicijski radovi u inozemstvu, Solarna oprema)

Tehnomont d.d koje u sastavu ima Marina Veruda ( nautički turizam)

"Generacije i generacije puljana izgradilo je ovo brodogradilište, te upravo zahvaljujući i koristeći generacijska iskustva, stečena znanja i vještine kao i dokazane reference i dugogodišnju tradiciju nastojimo očuvati održivost brodogradnje kao djelatnosti. "

"Misliti dobro je mudro;

planirati dobro je mudrije;

raditi dobro je najmudrije"

Novosti

Novi ugovori za Tehnomont Brodogradilište Pula

Nastavlja se uspješna suradnja Tehnomont Brodogradilišta Pula i Samba Marin AS.

23. prosinca 2024. godine potpisani su novi ugovori o gradnji brodova između Tehnomont Brodogradilišta Pula i Samba Marin AS

Novi ugovor za Tehnomont

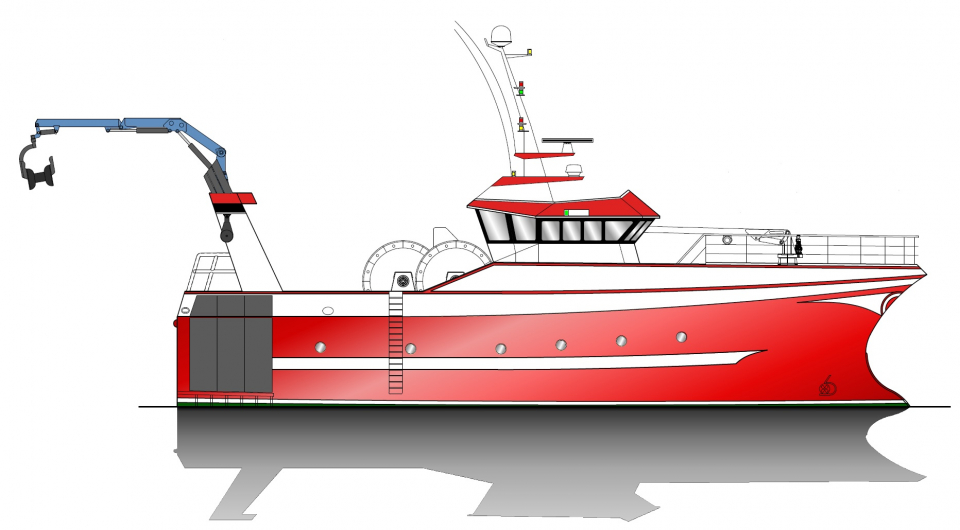

Dana 18.10.2023. potpisan je Ugovor o gradnji 28 m Hibridnog servisnog broda, između SAMBA MARIN AS iz Norveške i Tehnomont Brodogradilišta Pula d.o.o.

PRIMOPREDAJA 25,5 M VATROGASNI BRODOVI - GRČKA

15.12.2023. u Pireju, TEHNOMONT – BRODOGRADILIŠTE PULA d.o.o. je isporučilo dva 25,5 m Vatrogasna broda Grčkom naručitelju Ministarstvu civilne zaštite i klimatskih promjena.

VišePRIMOPREDAJA 17M PATROLNIH BRODOVA - CIPAR

15.09.2023. u Limassolu TEHNOMONT – BRODOGRADILIŠTE PULA d.o.o. je isporučilo tri 17 m Patrolna broda za pomorsku policiju Cipra.

VišePORINUĆE DVA 25 M ALUMINIJSKA VATROGASNA BRODA

Dana 29.09.2023. u TEHNOMONT - BRODOGRADILIŠTU PULA d.o.o porinuta su dva 25 metarska aluminijska vatrogasna broda TEHNOMONTOVE gradnje br. 123 i 124,

VišeNovi ugovor za Tehnomont

Dana 28.07.2023. potpisan je Ugovor o gradnji 26 m Hibridnog servisnog broda, između Moen Marina AS iz Norveške i Tehnomont Brodogradilišta Pula d.o.o.

Više